Avvy Group is involved in programming and system integration for a broad range of PLC, HMI and SCADA applications, from simple remote I/O to complex process control for municipal and industrial facilities.

Our PLC and SCADA Design & Programming services include:

PLC Logic Programming: Our team of highly specialized engineers and programmers write PLC programs using ladder logic, function block diagrams, structured text and instructional lists, and have adopted the IEC 61131 international standard for PLC programming - which is intended to reduce the complexity of programming different PLC models. Our team has vast experience in PLC programming for leading manufacturers including Siemens, Allen Bradley, GE, and Control Microsystems.

HMI Development: Avvy Group has a broad range of HMI development experience and is certified in the industry’s leading HMI software applications including InduSoft Web Studio, Wonderware InTouch, Intellution iFix, and Siemens Simatic WinCC. We support the entire HMI development process including Microsoft SQL, ActiveX controls and .NET controls integration. Our graphical user interfaces (GUI) are uniquely developed for each SCADA project and client. We actively integrate access to real-time data, automated reporting, smart phone and tablet enabled functions, secured web access clients, and surveillance device notifications to provide a total HMI solution deployment.

Avvy Group offers specialised condition monitoring services to industries. Our core condition monitoring services are;

- Alignment

- Balancing

- Design and Drafting

- Failure Analysis

- Finite Element Analysis

- Non Destructive Testing

- On-line Monitoring

- Strain Gauging

- Thermal Imaging

- Vibration Analysis

Alignment

Avvy Group provides a number of laser alignment services for machinery, with both shaft alignment and geometric alignment capabilities.

We specialise in the precision alignment of pumps, gearboxes, turbines, cardan shafts and vertically driven machines. Our equipment is also capable of aligning complicated machine trains and providing advanced laser services such as thermal growth measurement and ‘Live Trending’ of dynamic alignment tolerances during machine operation.

Balancing

Avvy Group offers quality single and multi-plane balancing services on equipment. Shop balancing is conducted at our workshop for rotors up to 2000mm in diameter and 3000mm bearing centres, with a 3000kg capacity. We also specialise in on-site balancing for all vertically and horizontally-driven items, and can cater for both centre and over-hung configurations.

Design and Drafting

Avvy Group offers a complete design and drafting service for all mechanical and basic structural requirements. Our qualified in-house engineers have been exposed to a wide range of industry-related problems and are proficient in the use of 3D/CAD modeling, finite element analysis (FEA), modal analysis and rotational resonance software.

The drafting services we offer can see your idea come to life in 3D, including the ability to simulate its operation prior to physical prototype construction if required. Our design team offers stress, deflection, stability and life-cycle analysis for all applications. Our mechanical engineers can often improve structural cracking and machine operating problems through the design of unique component modifications, and are also well-equipped to conduct shaft, drive-train and basic structural designs. Where applicable, all of our design work is combined with ‘physical’ vibration data collected from the machine to reduce the number of engineering assumptions used during calculation.

Failure Analysis

Avvy offers a wide range of Root Cause Analysis (RCA) support services to assist with failure investigations. These services can be tailored to suit client needs.

Some of our more frequently adopted services are:- Metallurgical analysis of failure surfaces

- Load testing of failed components

Finite Element Analysis (FEA)

FEA is a mathematical-based principle that allows engineers to predict stresses, deflections and critical operating speeds based on ideal operating conditions. Avvy uses a software that allows FEA to be applied to most structures and machine components that exist in industry.Our engineers are experienced in using this technology to provide the following services:

- The use of comparative methods to improve a component’s resilience to cracking under typical load conditions

- The use of comparative methods to help improve the flow of stresses throughout a component and optimize material usage and costs

- Estimation of component life based on load prediction at critical locations throughout the component under typical loading and speed conditions

- Influence of the air/moisture ratios on fan operating stresses

- Quality video files of 3D modeling outcomes and comparisons

- Minimum thickness estimation of in-situ materials

Non Destructive Testing

Avvy offers a comprehensive NDT service tailored for industry. Our qualified technicians are skilled in the use of visual, dye-penetrant, magnetic particle (MPI) and ultrasound (UT) methods. NDT services includes; crack-testing, weld checking, visual inspections and thickness testing inside pressure vessels. Avvy is highly experienced in conducting periodic inspections on turbine blades, fan blades, pins and chains and will customise an NDT solution to cater for individual client needs.On-line Monitoring

Avvy is on the fibre optic network, which has enabled us to provide timely remote online monitoring services at weekly, daily and even hourly intervals.

Once the monitoring equipment and vibration sensors have been installed on your site, we can view the machine data directly from our office. This gives our dedicated vibration analysts 24/7 feedback of what is happening to your machinery.

PDS can work with clients to develop user-friendly interfaces to view vibration data as numeric values, and even set up alert protocols if alarm levels are exceeded.

Strain Gauging

Strain gauges can be used to measure the in-service strain experienced within a particular material. The actual structural stresses can then be determined and used as a basis for maintenance decisions, design changes or fatigue life assessments.

Avvy has performed strain gauging on a wide variety of structures including tanks, cranes, grabs and tipplers. The data has then been used to determine the effect of impact events, perform design checks, conduct fatigue investigations, monitor levels in tanks as part of a wider control system, and quantify and record load cycles.

Thermal Imaging

Avvy has a number of experienced technicians trained to conduct thermal imaging surveys and analysis. Our equipment has the capability of measuring temperature ranges between -20°C and 800°C, with results provided in a standardised reporting format.

This technology is most frequently used by clients as a means of detecting faults in wiring, electrical panels and control cabinets, with many other uses in industry. Our range of services can be catered to suit any equipment investigation needs, routine checks or temperature trending on machinery.

Vibration Analysis

Avvy offers full range of consulting services in the field of vibration, including fault diagnosis and severity trending of existing problems. We can conduct site auditing, database setup and routine data collection for fixed and variable speed machines across all forms of industry.

Our experienced team can also offer in house, engineering-based analysis of troublesome equipment using resonance, damping, run-up, coast-down and Operation Deflection Shape (ODS) services.

Avvy can assist with sales, setup and support for a wide range of Prüftechnik Condition Monitoring and Online Monitoring systems. This technology is is specifically designed to automatically collect data from constant and variable speed machines without the need for human involvement. Optional features also allow data to be viewed on ‘Citect’, stored via USB or sent directly to our head office for routine analysis.

The use of this technology can be tailored to suit client needs, where it is ideally suited to the monitoring of critical or hard-to-reach equipment and machines that operate in intrinsically safe areas.

- Smart metering

- Power Quality

- Tariff Analysis & Assured Supply Capacity

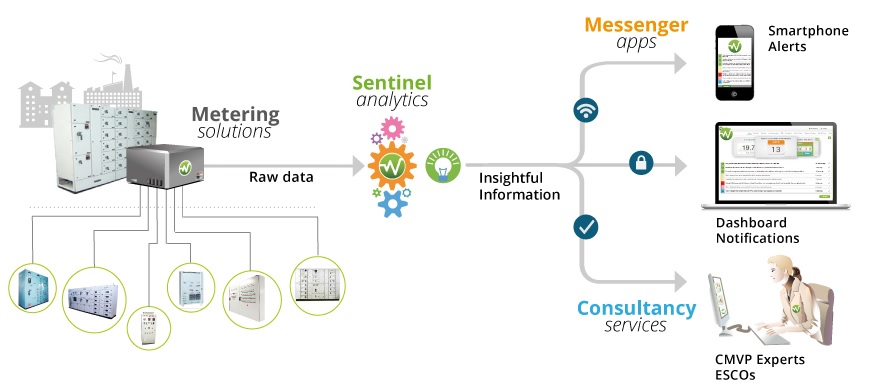

To effectively manage your energy, the ability to see what, when and where your energy is being used is a valuable asset. A smart meter takes automatic readings of your energy usage, sends the readings to a server or a communications link to central place; this data is then available at the company’s convenience for proper analysis.

At Avvy Group, we have current technologies to enable energy managers to efficiently track electrical energy consumption. We have state of the art Electrical Power Logging Meters for metering and monitoring these electrical parameters real-time;

- Voltage V1, V2, V3, Vlnavg, V12, V23, V31, Vllavg

- Current I1, I2, I3, In, Iavg

- Power P1, P2, P3, Psum

- Reactive Power Q1, Q2, Q3, Qsum

- Apparent Power S1, S2, S3, Ssum

- Frequency F

- Power Factor PF1, PF2, PF3, PF

- Energy Ep_imp, Ep_exp, Ep_total, Ep_net, Epa_imp, Epa_exp,

- Epb_imp_Epb_exp, Epc_imp, Epc_exp

- Reactive Energy Eq_imp, Eq_exp, Eq_total, Eq_net, Eqa_imp,

- Eqa_exp, Eqb_imp, Eqb_exp, Eqc_imp, Eqc_exp

- Apparent Energy Es, Esa, Esb, Esc

- Demand Dmd_P, Dmd_Q, Dmd_S, Dmd_I1, Dmd_I2, Dmd_I3

- Load Features

- Four Quadrant Powers

Contact our regional offices for more information regarding this new technology.

There are many varying facets and potential problems for the electricity consumer which includes inefficient energy consumption, poor power quality and inadequate distribution systems. We offer solution to ensure the incoming supply is working to its maximum potential.

Power Factor Correction (PFC) - Power Factor correction is still one of the most effective ways of reducing maximum demands, liberating system capacity and reducing cost of electricity. Harmonic Filters - Harmonic disturbance is one of the most common system problems which has grown with the increased use of switch-mode power supplies in modern electrical equipment.

At Avvy Group, we provide Power Quality Analysis and PFC services.

Tariff Analysis & Assured Supply Capacity

To gauge if you are getting “best value” for your supply Avvy Group can analyse your usage data to establish if your site is on the correct tariff structure for your usage pattern.

The Assured Supply Capacity (ASC) is for Maximum Demand 05-08 and Half Hourly 00 Profiles only and forms part of your tariff. The ASC is set when the supply is initially installed and where there has been a change of process/business at a site the ASC may be reduced leading to a reduction in charges.

Bill validation

We offer a bill validation service to highlight any errors in agreed rates. When a contract has been placed, and as part of our continuing customer service, we will monitor each invoice received to ensure that the correct rates have been applied to the correct site. With this information we are able to build up a picture of your sites’ consumption, this can be compared to the years previous. This information can prove invaluable when energy saving devices have been installed.In combination with Smart Metering facilities this can lead to closer control of your utility budgets. In addition to the ongoing validation we can offer a Historical Validation Service where we can look at past billing, over an agreed, pre-determined period.

-

Industrial Engineering

Civil and Structural Engineering

Water and Environmental Engineering

Mechanical and Mechatronics Engineering

Electrical and Electronics Engineering